In this Q&A with Do Thanh Huyen, we look at how foreign investors can qualify for preferential tariffs using the EVFTA in the automobile industry.

With a rapidly expanding market fueled by a fast-growing middle-class, Vietnam has been an attractive destination for major automobile manufacturers from Japan, Korea, the US, and the EU for several years. The EU-Vietnam free trade agreement (EVFTA), which came into effect on August 1, 2020, has made the market even more promising for European manufacturers since high tariffs imposed on EU automobile exports will be eliminated after seven to 10 years to enable full access to the market and increase the competitiveness of EU manufacturers.

To learn more about the benefits of the EVFTA on the automobile industry, our Business Intelligence Assistant Manager – German Desk, Do Thanh Huyen, conducted a webinar on how investors can qualify for preferential tariffs for the automobile industry. During this webinar, Huyen discussed Vietnam’s automobile industry potential, including emerging opportunities and barriers, and finally ideal market entry options for foreign investors. The webinar can be viewed here.

We highlight some insights below:

Can you tell us about Vietnam’s automobile industry?

Vietnam’s automobile industry has been in an expansion mode with the passenger market growing the fastest. Between 2012 and 2015 annual growth reached 90 percent. The pandemic is likely to affect this growth in the short-term but growth will likely rebound in the long term.

What are some of the growth drivers?

There are several growth drivers, but I would list the most important which are: macroeconomic growth, socio-cultural trends (status symbol, convenience), increasingly liberalized trade environment (free trade agreements), government policy to reduce motorcycles, and rising disposable income.

Vietnam’s top import markets are ASEAN followed by the EU, Japan, China, and Mexico. Top export markets are the US, UK, ASEAN, EU, and China.

Vietnam’s market is dominated by Toyota, followed by Honda, and Kia with the Toyota Vios model the most popular in the domestic market.

Can you give us an industry overview?

Vietnam has around 56 automotive plants with 18 foreign-invested companies and 38 domestic companies. Toyota has the largest market share of about 26 percent, followed by Thaco and Mitsubishi.

Vietnam’s localization rate has been low due to the underdevelopment of supporting industries. For cars, this is just about 7 to 10 percent. Vietnam’s localization rate is the lowest compared to ASEAN countries such as Thailand, Indonesia, and Malaysia.

Vietnam imports most of its automobile components from South Korea, Japan, and ASEAN countries. There are about 250 component manufacturers dominated by SMEs with about 100 tier 1 suppliers and 150 tier 2 and tier 3 suppliers.

High-value production such as engine production and transmissions have not been able to develop. Localized products are typically of low value such as tires, mirrors, and plastic products. Due to the number of free trade agreements, domestic production is a disadvantage compared to completely built units (CBUs).

However, local companies such as VinFast and TC motors keen to change this. VinFast unveiled its automobile factory in 2019 making it the first local car manufacturer to do so in Vietnam.

While Japanese and Korean manufacturers dominate the auto market, there is potential for EU investors to establish a presence.

What are some opportunities with the EVFTA in effect?

Vietnam’s import tariffs on autos from the EU will be eliminated in 10 years as per the EVFTA. Tariffs, currently are high which is a deterrent to investors.

Automobile products, however, must be wholly obtained or undergo sufficient working or processing in Vietnam or EU member states to acquire origin status.

In addition, due to the EVFTA, Vietnam will accept several certificates in line with UN and EU regulations without further requirements for testing and certification. These include whole passenger cars as well as automobile components.

What are some trade barriers?

While trade barriers on automobile import products have been relaxed, the domestic auto industry continues to be prioritized. The Vietnamese government is looking at ways to safeguard the domestic automobile industry against foreign rivals. Not only this, EU manufacturers will have to compete with ASEAN manufacturers as well. Under the ASEAN FTA, customs duties on automobiles from ASEAN countries are eliminated.

In addition, the manufacturing of motor vehicles and transport equipment remains restricted. We have observed that investment in automobiles and motorbike assembly is subject to the Vietnamese government’s planning who may give preference to local investors. These could be in terms of production quantity to meet the demand of the domestic market and location preferences.

What are some market entry options?

There are several market entry options for entering the Vietnamese market such as a joint-venture, a manufacturing facility, or a foreign-owned enterprise.

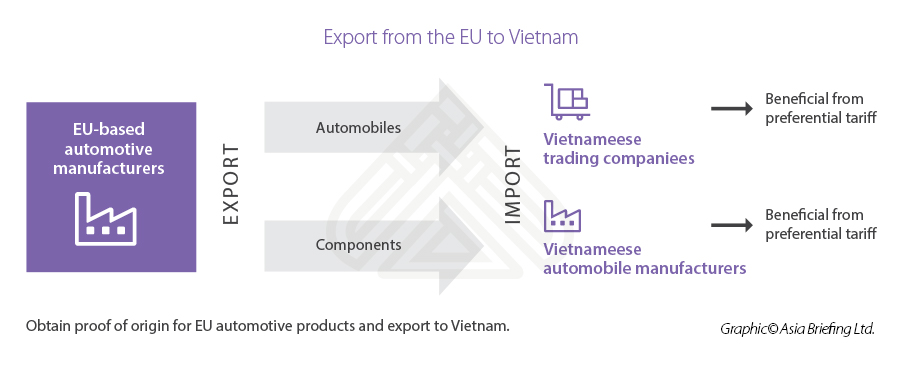

For the automobile industry, we advise that EU investors can either export to Vietnam or engage in auto assembly in Vietnam. Investors can either export automobiles or export components as shown in the infographic below.

Vietnam customers are subject to high costs and taxes, therefore investors can consider exporting passenger cars or car parts for the passenger car market. Most after-market activities are concentrated in Tier 1 cities like Hanoi and Ho Chi Minh City, which account for 40 percent of total passenger vehicles in the country.

It is important to note that for exporting, manufacturers are required to submit proof of origin knows as the REX system to customs authorities.

Investors considering manufacturing should consider a joint venture with a local manufacturer as these are supported by the government. In addition, auto components originating in the EU are granted preferential tariffs under the EVFTA.

However, investors should be aware that an underdeveloped supporting industry and a shortage of skilled labor may lead to high production costs.