This is the largest ship that the Dung Quat Shipyard as well as any other shipyards in Vietnam has repaired and converted so far

After six months of hard work, engineers and workers at a Vietnamese shipyard have completed the conversion of a crude oil tanker, as large as an aircraft carrier, into a sea-floating oil storage tank for delivery to Nigeria soon.

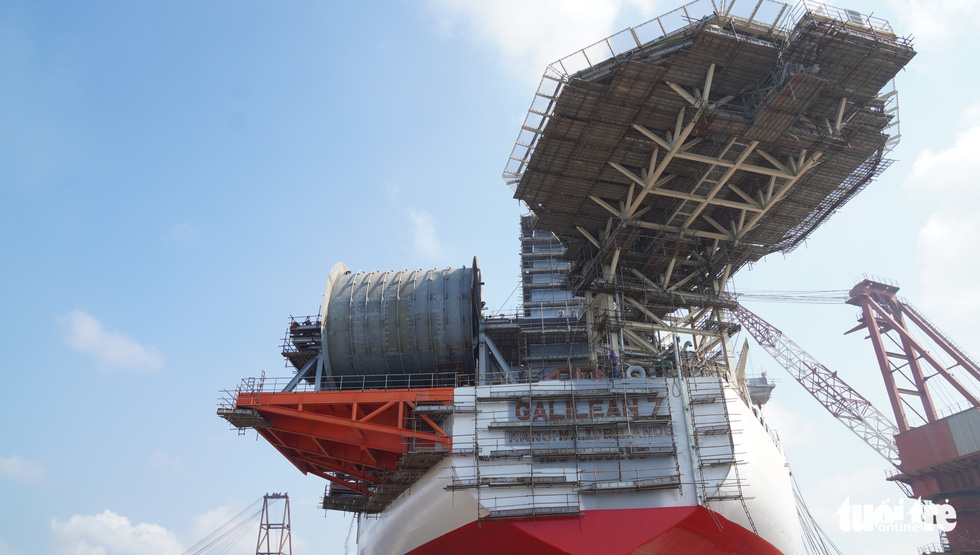

The vessel Galilean 7, one of the Suezmax crude oil tankers, left the repair dock at the Dung Quat Shipyard in Quang Ngai, a central province of Vietnam, in late April after months of conversion.

This facility, which is 334 meters long and 58 meters wide, has been converted into a floating storage and offloading (FSO) vessel, which can accommodate two million barrels of crude oil at a time.

This is the largest ship that the Dung Quat Shipyard as well as any other shipyards in Vietnam has repaired and converted so far.

|

| It required a tugboat (at the prow of Galilean 7), a push boat (at the stern) and six support boats (on the sides) to take the sea-floating oil storage tank offshore. Photo: Hoai Anh / Tuoi Tre |

The successful conversion of Galilean 7 is deemed as a strong introduction to the world of Vietnam’s ability to build and repair large vessels.

Galilean 7 was towed to the shipyard’s dry dock, capable of 400,000 DWT, in mid-October 2020 in the first phase of a repair contract worth over US$10 million.

The conversion process was divided into two phases. The first phase, from October to December 2020, was mainly for surveys and assessments of the conditions of the ship, oil tanks and other components.

The tanker was later towed to the sea again and waited there until February this year, when the second phase started, focusing on installation of specialized equipment.

Such equipment, which is fabricated based on purchase orders only, include a 135-ton airport cluster, a 22-ton cargo offloading hose reel system and a new pipeline system.

|

| As requested by the Nigerian billionaire, the floating oil storage tank has a helipad (on the left) to facilitate the access to the vessel when it is anchored offshore. Photo: Hoai Anh / Tuoi Tre |

After the spread of the news that the vessel Galilean 7 has been converted in Vietnam, many shipping lines in the Middle East have had their vessels repaired at the Dung Quat Shipyard.

The Galilean 7 conversion contract has served as evidence that Vietnam’s shipbuilding industry is capable of competing with its counterparts in the region.

The shipyard has engaged in the Galilean 7 conversion project for two years since it heard that a billionaire in Africa wanted to buy a tanker to convert it into an FSO, Nguyen Anh Minh, deputy general director of the shipyard, said.

Among the factors thanks to which the Dung Quat Shipyard won the contract, the most important one was its experience and capability in building dozens of large vessels in Vietnam.

Another advantage was that the shipyard was transparent in its contract-related documents and showed its persistence and determination to finish the project.

|

| Vietnamese engineers and workers at the Dung Quat Shipyard in the central province of Quang Ngai Province spent months working hard on conversion items to make their products meet international standards. Photo: Hoai Anh / Tuoi Tre |

An objective reason was that many factories in China operated less efficiently in 2020 due to the impacts of the COVID-19 pandemic.

By far, there has been no other ship repairers in Southeast Asia, except for those of Singapore, which operate a dry dock with a large capacity like that of the Dung Quat Shipyard.

After being towed safely from the dry dock, the ship Galilean 7 – now an FSO vessel – will soon begin her 27-day voyage from Vietnam to Nigeria, where it will be handed over to its new owner, one of the richest billionaires in Africa.

The captain and crew that will steer the ship during the journey are Vietnamese.

|

| Nguyen Thi Thao, a female worker specializing in steel sheet cutting at Dung Quat Shipyard, is satisfied with her current job that properly sustains herself and her family. Photo: Hoai Anh / Tuoi Tre |

|

| Dung Quat Shipyard had to mobilize all of its existing scaffolding systems and hire more scaffolding from outside to ensure the progress of the repair and conversion of the giant oil tanker – a great task requiring thousands of workers. Photo: Hoai Anh / Tuoi Tre |

|

| The oil pipeline system on the deck is a new piece of work requested by the ship owner. These pipes were imported from abroad and installed by Vietnamese workers. Photo: Hoai Anh / Tuoi Tre |

|

| Vietnamese workers install and complete the helipad on Galilean 7. This helipad was imported from Dubai (United Arab Emirates). Photo: Hoai Anh / Tuoi Tre |

|

| The 22-ton cargo offloading hose reel system onboard the sea-floating oil storage tank. Photo: Hoai Anh / Tuoi Tre |

|

| The 22-ton cargo offloading hose reel system is fabricated at a factory of the Dung Quat Shipyard. Photo: Hoai Anh / Tuoi Tre |

|

| The cargo offloading hose reel system is moved out of the factory for installation on the vessel Galilean 7. Photo: Hoai Anh / Tuoi Tre |

|

| The conversion of Galilean 7 into a floating storage and offloading (FSO) was divided into two phases. The first phase, from October 2020 to December 2020, was mainly for surveys and assessments of the conditions of the ship, oil tanks and other components. Photo: Hoai Anh / Tuoi Tre |

|

| The second phase of the conversion started from February, focusing on the fabrication and installation of special equipment. This great project not only brings income to the workforce of the Dung Quat Shipyard through the year of COVID-19 pandemic, but also enhances the prestige of Vietnam’s shipbuilding and repair industry. Photo: Hoai Anh / Tuoi Tre |

|

| Nguyen Cong Thi, a young engineer in charge of commanding the tasks on the deck of Galilean 7. He was in charge of making assignments to more than 600 workers every day. Photo: Hoai Anh / Tuoi Tre |

|

| Workers are seen standing on the scaffolding system to paint the hull of the converted vessel Galelian 7. Photo: Hoai Anh / Tuoi Tre |

|

| The ship is too tall, making the re-decoration of the name of the ship and the shipyard’s logos an uneasy task. Photo: Hoai Anh / Tuoi Tre |